Innovative Robotic Arm Revolutionizes Maritime Repair, Paving the Way for Future Ship Maintenance

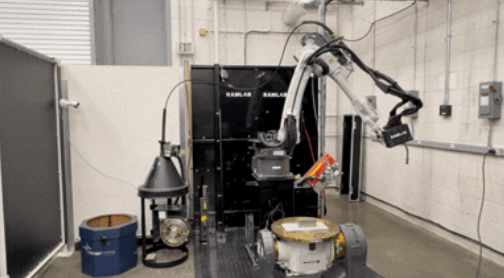

To support research aimed at strengthening the United States’ maritime industrial base, the Johns Hopkins Applied Physics Laboratory (APL) in Laurel, Maryland, has installed a new industrial robotic arm at its advanced manufacturing facility. The system, known as the RAMLAB MaxQ robot, will be used to study, test, and validate advanced repair and manufacturing methods, with the goal of identifying the most effective ways to transfer these capabilities to small businesses and industry partners.

“Repair is one of the most challenging aspects of maritime sustainment, yet it is essential because repairing components is often faster than manufacturing new parts from the ground up,” said James Borghardt, APL’s Expeditionary Logistics program manager. “With this new capability, APL can evaluate and refine additive manufacturing techniques that make repair more practical for government and industry partners, ultimately enhancing the agility and resilience of the maritime industrial base.”

The initiative builds on APL’s ongoing efforts to support and modernize the U.S. maritime industrial base through a range of programs and projects. These include deployable directed energy deposition systems, the adoption of laser powder bed fusion technologies, materials discovery efforts linked to national security, and close collaboration with industry to improve advanced manufacturing tools, processes, and standards.

Traditionally, the construction or repair of large maritime components—such as propellers—requires custom molds and costly assembly-line infrastructure. These requirements often represent a significant financial barrier for small and medium-sized suppliers. By enabling large-format manufacturing and repair without extensive fixturing, the new robotic system could lower entry barriers, broaden supplier participation, and help diversify the defense industrial base by making advanced capabilities more accessible to smaller businesses.

APL’s research team is developing and evaluating new repair and manufacturing solutions for both military and civilian maritime applications. Featuring a six-foot operating radius and a large build volume, the robotic arm is capable of maneuvering large structural and mechanical components within a relatively compact workspace. The system employs wire arc additive manufacturing, a proven welding-based process that uses lower-cost wire feedstock, helping to reduce costs while supporting efficient production and repair of large-scale equipment and hardware.

The robotic arm is also equipped with integrated sensing, scanning, and adaptive control systems that enable it to detect defects in large, irregular, or damaged components. These capabilities support the development of semi-autonomous repair pathways, although human oversight remains essential. APL researchers will conduct simulations prior to production runs to ensure the system operates within its physical limits, while skilled operators will remain involved to guide processes and complete parts to the required standards of accuracy and reliability.

“These technologies allow us to carry out repairs that are more intelligent, more precise, and significantly faster,” said Carly Mayhood, a maritime engineer and project manager at APL. “Through continued research, we aim to further improve repair and manufacturing processes, reduce the Navy’s dependence on costly disassembly or full part replacement, and keep ships mission-ready with reduced downtime.”

Information courtesy of Johns Hopkins APL